Project Description

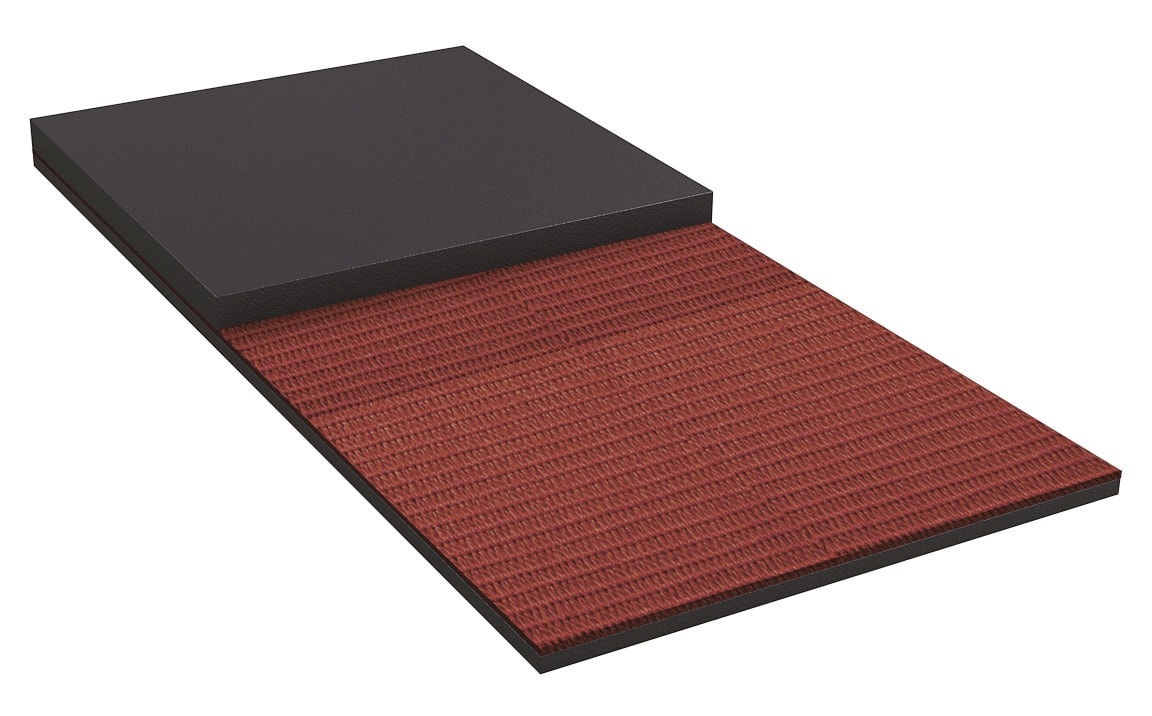

Prima FLEX

EPP textile belts for extreme operational conditions and low elongation values

EPP textile belts for extreme operational conditions and low elongation values

Our single layer PRIMA FLEX belts boast excellent resistance to cuts, tears, and impacts. They are therefore used on conveyors that are subject to very signi cant stress.

The single layer EPP textile has been speci cally designed to guarantee reduced elongation under loading, stability in the lengthwise direction, excellent resistance to impacts due to a we which is both robust and exible, and excellent troughability. This speci c combination of warp and we threads gives the PRIMA FLEX belt special properties that also enable it to cope with certain problems speci c to conveyors with a short course on the tension system, and conveyors with drums of small diameter. Another advantage: The mechanical splicing approach can successfully be applied to PRIMA FLEX belts.

Mining

Ciment works & Quarries

Steel industry

Agri-food

Waste recovery & recycling

ADVANTAGES OF PRIMA FLEX BELTS

ADVANTAGES OF PRIMA FLEX BELTS

Excellent resistance to impacts, tears, and cuts

Elongation under operating conditions reduced by 30% compared to the traditional textile belt

Suitable for conveyors with a short tension course

Excellent troughability and guiding properties

Very suitable for the mechanical splicing approach

Excellent bond strength achievable through the hot vulcanizing method

Our PRIMA FLEX belts can be provided with di erent types of rubber covers, resistant to abrasion, grease and oils, heat, cold or fire

Abrasion-resistant

Grease-resistant

Heat-resistant

Fire retardant